Productivity Manufacturing industry

We aim to create new services by supporting manufacturing workplaces.

Improvement in quality and precision of manufacturing

The adoption of AI is moving ahead even in the workplaces for manufacturing that is the pride of Japan.

In mass production workplaces to date, machines with recorded operation procedures have been called on to repeat the same movements. Moving forward, as lower volumes of production for a greater variety of products become more common, the technology nurtured in these environments will begin being applied in other areas such as agriculture and the home. As this happens, machines will be needed that can respond flexibly according to the situation, and that can optimize the system.

To this end, technology will be needed that can automatically generate robot work movements. Research is being conducted on robots that can implement automated work process planning by presenting the final state of an assembly procedure. In addition, a simulated factory will be constructed that adds not only the situation but also processing procedure, as we work on understanding the operational state of moving machinery and failure prediction.

In this field, we have entered the verification testing stage using prototypes in the development of a system that detects signs of failures and danger in wind power-generating equipment, and that enables predictive maintenance. We are also developing technology to enable robots to handle objects without form such as towels or clothing in which their shape cannot be modeled beforehand. Here, the latest technology is used including imitation learning methods that utilize deep neural networks.

The potential of AI is moving beyond the role of achieving greater efficiency that has been the mandate of machines heretofore, and onto improving quality and accuracy.

In mass production workplaces to date, machines with recorded operation procedures have been called on to repeat the same movements. Moving forward, as lower volumes of production for a greater variety of products become more common, the technology nurtured in these environments will begin being applied in other areas such as agriculture and the home. As this happens, machines will be needed that can respond flexibly according to the situation, and that can optimize the system.

To this end, technology will be needed that can automatically generate robot work movements. Research is being conducted on robots that can implement automated work process planning by presenting the final state of an assembly procedure. In addition, a simulated factory will be constructed that adds not only the situation but also processing procedure, as we work on understanding the operational state of moving machinery and failure prediction.

In this field, we have entered the verification testing stage using prototypes in the development of a system that detects signs of failures and danger in wind power-generating equipment, and that enables predictive maintenance. We are also developing technology to enable robots to handle objects without form such as towels or clothing in which their shape cannot be modeled beforehand. Here, the latest technology is used including imitation learning methods that utilize deep neural networks.

The potential of AI is moving beyond the role of achieving greater efficiency that has been the mandate of machines heretofore, and onto improving quality and accuracy.

-

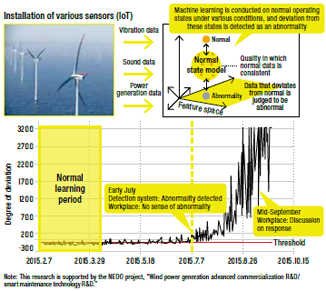

Theme1Detecting signs of failures in wind power generation

A system is currently in development that uses machine learning to detect signs of equipment failure that would be difficult to detect from visual inspection. Currently, sensor data is being collected from 41 actual domestic large wind turbines, and large-scale verification testing is being conducted. The goal is for a paradigm shift from responding after the fact to maintenance that prevents problems and maintains safety. -

-

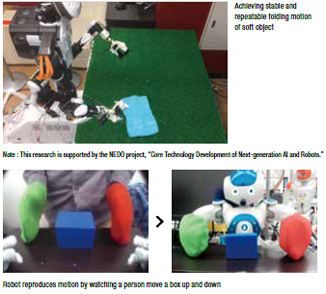

Theme2Imitation robot

Through end-to-end learning of deep neural networks, the relationship between visual information and teaching motion is learned, as “imitation learning methods” are being developed that enable motions of which teaching was difficult, such as picking up unknown objects, and folding of soft objects. A “teaching-less” robot is definitely not just a dream. -

Future prospects

- Expansion of breadth of failure and danger sign detection, and improvement in prediction accuracy

- Establishment of key robot technology and greater integration

- Creation of a robot that can appropriately respond to changing and complex environments and tasks